13/09/2024

ERP in textile industry: advantages, risks, and key requirements

Enterprise Resource Planning (ERP) is a tested technology application that offers a competitive edge to businesses in the global economy. EPR is particularly crucial in the textile industry, known for its labor-intensive nature and complex network of input materials, products, and supply chain connections.

Implementing Enterprise Resource Planning (ERP) has yielded many benefits, particularly in enhancing cohesion across the supply chain. In recent decades, technological advancements have optimized various areas, including procurement, inventory management, workforce and payroll administration, and have expanded into other areas such as web-based data management and automated design and production. These applications fall short of meeting the changing demands prevalent in the textile and garment business regardless, especially when improved integration among different departments is necessary. The ERP system, however, can overcome this challenge.

An EPR system acts as a central information hub, enabling businesses to efficiently manage resources for receiving, producing, and delivering customer orders enterprise-wide.

Before using EPR, different businesses and departments function independently, leading to significant gaps and delays. ERP facilitates integration, which significantly improves operational efficiency and reduces costs associated with disparate functional units.

Enterprise Resource Planning (ERP) brings 5 significant advantages to the textile industry

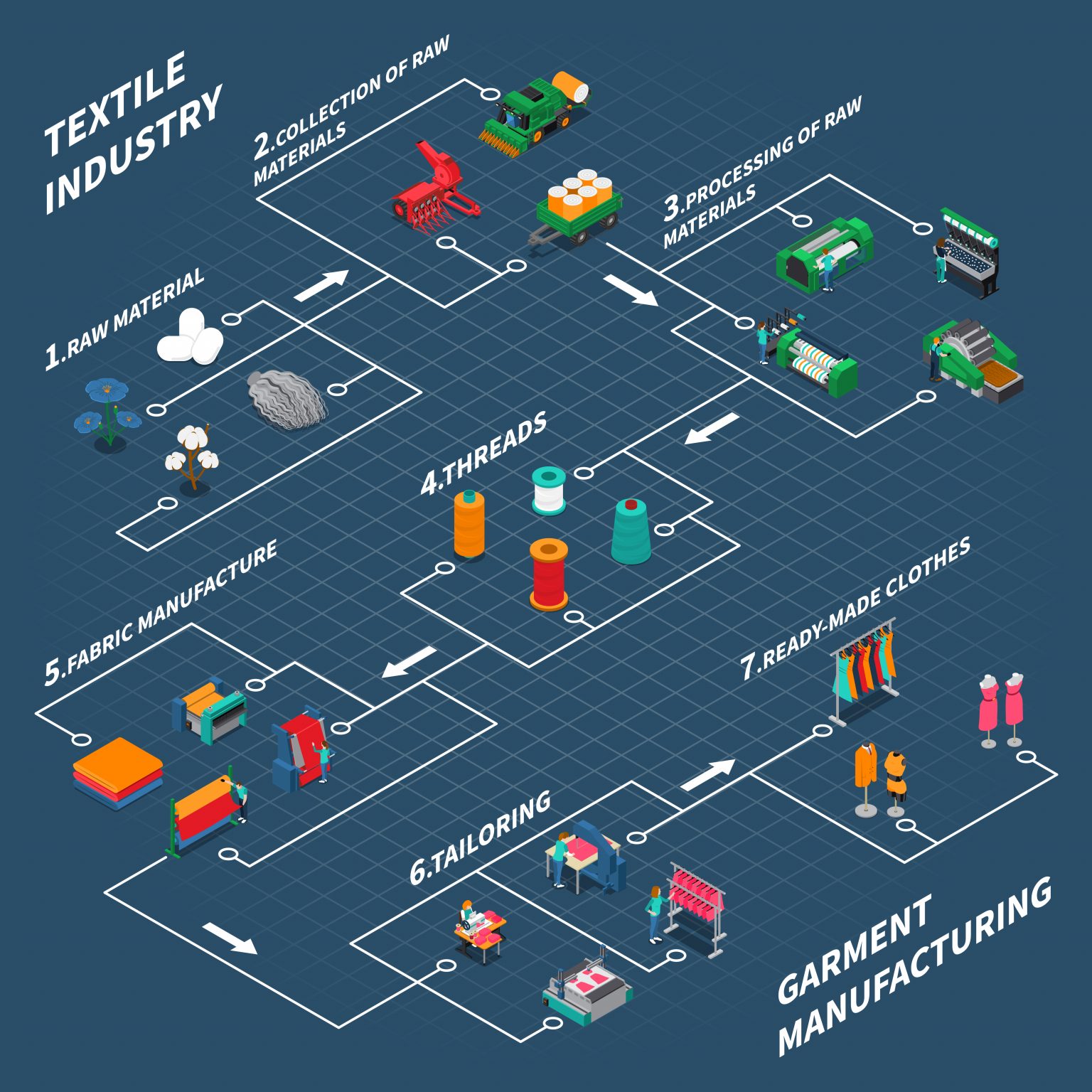

Take a look at this infographic. Simply click on the benefit to see the full version.

Despite offering various benefits, Enterprise Resource Planning (ERP) still poses certain risks, several of which are listed below

1. Data security

For individuals who do not own the entire system but purchase services from a third party, data stored in the cloud or within the domain of the service providers is at risk of unauthorized duplication or theft.

2. Senior management

Senior management plays a vital role in implementing an ERP system. When there is a lack of comprehension regarding ERP’s role in the business, an inadequate understanding of the business’s operational processes, or the implementation of bureaucratic decisions, failure is likely to occur.

3. Financial restrictions

Limited financial resources may hinder the installation of an ERP system, which requires investment targeting specific stages or priority areas

4. Lack of technology knowledge

Possessing the necessary technological know-how to operate an ERP system can be challenging for employees. Difficulties in transitioning from current work processes or adapting to new technology can impede the effectiveness of ERP implementation.

The textile industry is known for its labor-intensive nature and intricate network of input materials, products, and supply chain connections.

Using Enterprise Resource Planning (ERP) in textile industry can facilitate integration among departments and complicate business procedures

Textile enterprises must consider the following key requirements to guarantee effective deployment and utilization of an ERP system.

1. Devise a strategy

It is essential to devise a well-defined business strategy and vision for implementing an ERP system in the enterprise, ensuring the deployment is high on the agenda. One of the main reasons for ERP project failures is the company’s lack of vision and insufficient understanding of production and business processes, leading to misestimation of the ERP deployment

2. Identify areas of high-priority ERP implementation.

This allows businesses to save financial and labor resources by partially implementing the ERP system, provides more time for preparation and offers opportunities for experimentation. As a result, companies can avoid errors due to large-scale orders or financial constraints.

3. Selecting the appropriate ERP provider

Selecting the right ERP provider tailored to the size and specific needs of the business is crucial for a successful implementation. They will assist enterprises in installing, customizing, and training employees, which are the initial steps in effectively developing ERP.

4. Select the development team wisely

It’s crucial to assemble a diverse group of individuals from different departments with the appropriate skills and experience. This ensures a comprehensive understanding of the company’s production, business procedures, and other relevant aspects during the development phase. The person in charge of project management should be a part of the senior management team. They should lead the team, supervise the development and implementation process, and have strong communication and organizational skills to effectively coordinate with various internal and external departments.

5. Employee Training

Employees play a crucial role in the success of the ERP system implementation as end users. The training program should include two parts:

-

- Practical training sessions and simulations familiarize employees with the ERP interface and functionalities relevant to their roles in the organization

- Training focused on efficient change management to transition towards an organizational culture, which sustains the effectiveness of ERP in the long term

Moreover, providing continuous support and granting decentralized access to resources, such as user guides and FAQs, is essential to tackle any challenges that may arise post-deployment and to support ongoing training initiatives.

Translated from the article published in the August 2024 issue of Textile-Garment and Fashion Vietnam Magazine.

Share: